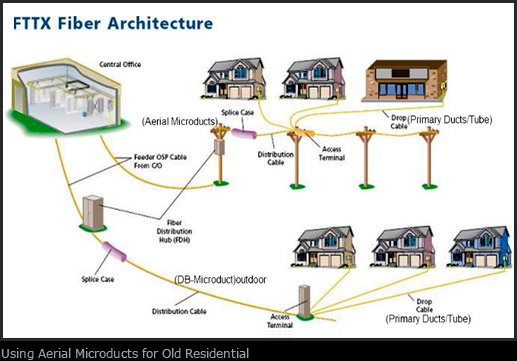

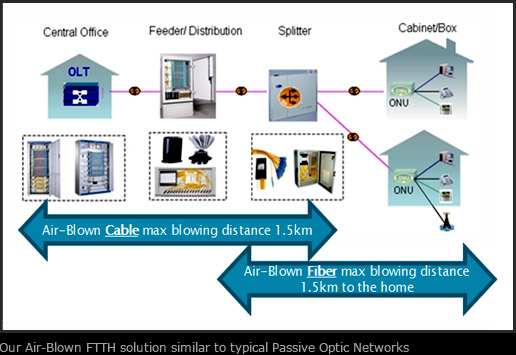

Air-Blown Fiber-to-the-Home (FTTH) is a technique to insert a microfiber also known as Air-blown fiber (ABF) or Air-blown Cable (ABC) into an array of 1-24 way of micro sub-ducts as long as 1.5km in one blow. This method uses an air compressor and blowing machine to float the fiber inside the micro sub-ducts making it friction free during the fiber push.

Air Blown System(ABS) originated from ABF(Air Blown Fiber) system in 1982 at British Telecom.

ABS is a flexible and cost-effective cabling system for installing optical fibers in all types of metropolitan, access networks and also in backbone network.

ABS creates a future-proof network ready for tomorrow's demanding applications. It also gives a cost-efficient rollout and maintenance, which creates the opportunity for increasing broadband penetration and reaching out to new users.

Our Product Concept:

- Direct Buried (DB) for outdoor

- Direct Install (DI) for indoor

- Aerial for outdoor (Pole to Premise)

Mechanical Properties:

- Tensile Strength (0.8W Rule)

- Crush Resistance (1000N applied over 100mm for 60secs and 400N for LSZH products)

- UV Resistance ( carbon black added to improve UV resistance)

- Chemical (good reistance to water, acids, solvents)